Lean management has emerged as a modern approach that challenges traditional ways of running operations. It teaches organizations to enhance business efficiency by rethinking what customers truly need and how every workflow can be aligned to continuously create that value.

Its core principle is simple: eliminate what’s unnecessary, focus on what adds value, and continuously improve the process. However, implementing lean management is not merely about cutting costs or speeding up work, it also requires a fundamental shift in how organizations view work as a whole.

To understand lean management in depth, let’s explore the following comprehensive overview.

What Is Lean Management?

Lean Management is a management approach focused on eliminating waste in every business process without sacrificing the value delivered to customers. This concept originated from the Toyota Production System (TPS) developed in Japan in the mid-20th century, and its principles have since expanded across industries, from manufacturing and logistics to healthcare and service companies.

At its heart, the lean method revolves around two main ideas: enhancing customer value and reducing non-value-adding activities. The value in question is not defined by the company but by the customer.

This approach goes beyond technical efficiency, it fosters a cultural transformation across the organization. Lean thinking instills the awareness that every individual, from operational staff to management, plays a crucial role in continuous improvement.

In this process, mistakes or inefficiencies are not seen as personal failures but as opportunities to improve the system. This philosophy makes lean not just a working method but a way of thinking that shapes a company culture that is more agile, transparent, and adaptable to change.

The Core Principles of Lean Thinking

Lean thinking is a mindset framework that places the customer at the center of all organizational activities.

James P. Womack and Daniel T. Jones, two pioneers who popularized this concept, identified five key principles of lean thinking that have become global guidelines for organizations.

1. Defining Value

Every process must begin with a clear understanding of what customers truly value. This value is not determined from the company’s internal perspective, but from the needs and expectations of the end user.

By embracing this principle, organizations can direct all their activities toward genuinely meeting customer needs.

For example, in the financial services industry, customers may value speed of service more than the number of available features. Therefore, efficiency efforts should focus on accelerating verification or approval processes, not adding more forms or unnecessary procedures.

2. Mapping the Value Stream

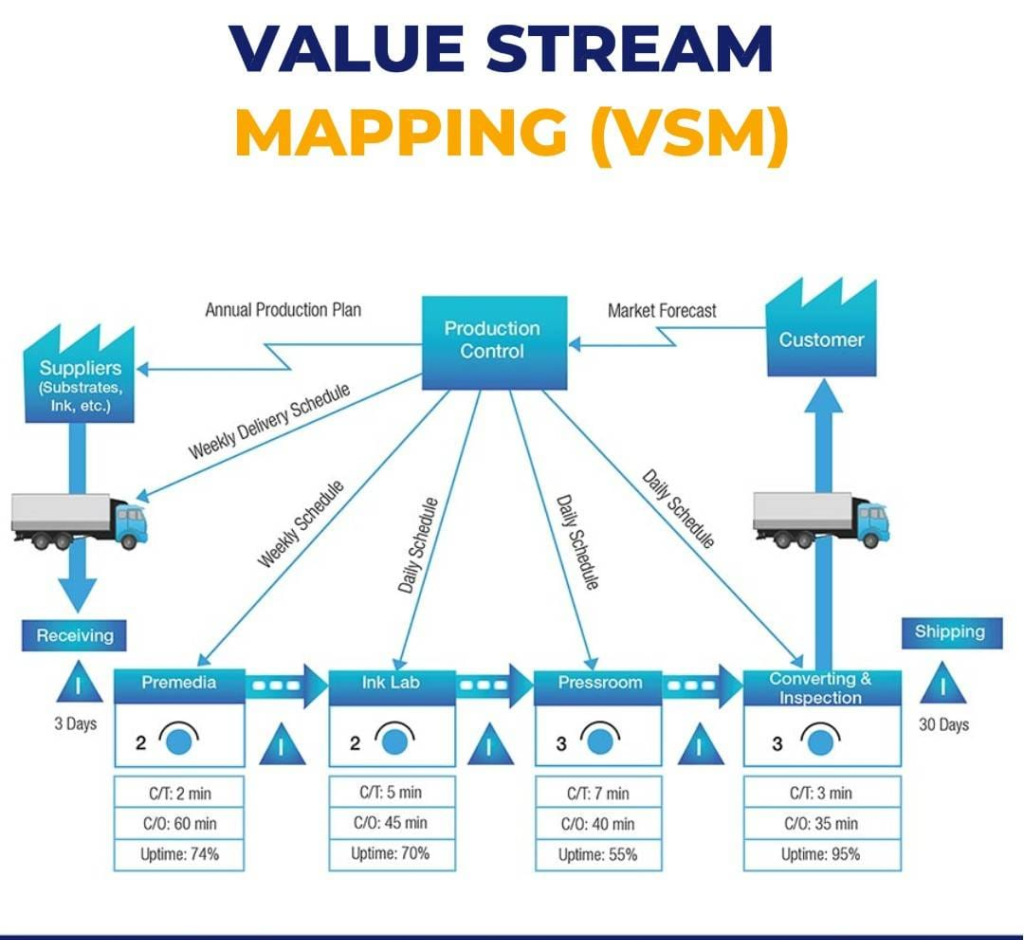

Once value is defined, the next step is to map all processes that contribute to creating that value. This process, known as Value Stream Mapping (VSM), is a visual technique used to depict every work stage from start to finish, complete with the time, resources, and potential waste involved.

Value Stream Mapping helps organizations filter their activities and distinguish between value-added and non-value-added processes. Non-value-adding activities become the primary targets for elimination, simplification, or automation.

3. Creating Smooth Flow

After identifying the foundational structure, the next goal is to establish a smooth and uninterrupted workflow so that processes can operate sustainably.

In practice, many organizations become trapped in layered systems and unnecessary procedures such as waiting for approvals, materials, or data which ultimately reduce the value delivered to customers.

Lean encourages work to flow seamlessly from one stage to the next without inefficient pauses. This often requires redesigning processes, reviewing bureaucratic layers, and improving cross-team coordination.

However, creating flow does not mean speeding everything up blindly it means ensuring that every part of the process moves in harmony toward a single goal: customer value.

4. Building a Pull System

Once the flow is established, the next challenge is maintaining balance between process rhythm and customer demand. Many companies operate quickly, but not necessarily accurately they still produce or serve based on forecasts rather than actual customer needs.

This is where the pull system principle comes in. It ensures that every activity is triggered only by real customer demand. By doing so, companies can avoid overproduction, work backlogs, and wasted time preparing things that may never be needed.

5. Pursuing Perfection

The journey toward lean excellence never truly ends. After defining value, creating flow, and balancing demand, the next stage is not to stop, but to continue improving. Here, the Kaizen philosophy or continuous improvement becomes the essence of Lean Management.

These five principles are interconnected, forming a mindset focused on both customer value and system efficiency. When consistently applied, Lean Thinking not only enhances productivity but also fosters a work culture that is collaborative, learning-oriented, and responsive to market changes.

Discover More : Understanding Standard Operating Procedure (SOP) as the Pillar of Organizational Governance

5 Benefits of Lean in Business Operations

The implementation of Lean Management brings a broad impact on how companies work and adapt. It not only increases efficiency but also strengthens a culture of continuous improvement across all levels. The following are several key benefits I have summarized:

1. Higher Operational Efficiency

As the name suggests, “Lean” helps companies identify and reduce non–value-added activities, making workflow faster and more resource-efficient. With streamlined processes, production time can be reduced and asset utilization becomes more optimal.

2. Improved Product Quality and Consistency

By focusing on error prevention and process standardization, Lean ensures more stable and predictable results. Quality no longer depends on final inspections but becomes an integral part of the working system itself.

3. Higher Customer Satisfaction

By focusing on the value truly desired by customers, Lean encourages companies to deliver relevant, timely, and consistent products and services. Quick responsiveness to customer needs becomes part of the competitive advantage of this method.

4. Employee Empowerment and Engagement

Lean fosters a collaborative culture where every individual is involved in improvement efforts. Employees are not merely executors but active contributors in creating solutions. This has a significant impact on increasing motivation, sense of ownership, and care toward work outcomes.

5. Organizational Resilience and Adaptability

Companies that implement Lean principles demonstrate greater resilience and adaptability to market dynamics or operational disruptions. A lean structure and transparent workflow mechanisms enable faster, data-driven decision-making processes without compromising overall system stability.

Overall, the implementation of Lean Management contributes significantly to improving efficiency, quality, and competitiveness. These benefits not only strengthen operational performance but also form a foundation for more adaptive governance and a continuous improvement mindset.

Challenges in Implementing Lean

Although the concept of Lean Management has proven effective across various sectors, its implementation is not always smooth. This is because Lean requires discipline, consistency, and the readiness of all company elements to change.

That is why, in practice, implementing Lean often faces significant challenges both technical and cultural.

1. Resistance to Change

One of the most common obstacles in Lean Management implementation is resistance to change. Many companies face difficulties aligning Lean principles with long-established systems and work cultures.

Lean demands a new perspective toward work, from merely performing tasks to actively participating in improvement processes. This paradigm shift often causes discomfort for some individuals because it disrupts old habits, authority structures, and routines previously seen as stable.

2. Lack of Top Management Commitment

Lean cannot run effectively without full support from top management. In many cases, Lean initiatives stop at the operational level because leaders view them only as efficiency projects rather than a cultural transformation.

However, Lean’s success depends heavily on consistent direction and exemplary behavior from leadership. When management fails to demonstrate real commitment, the expected change tends to remain superficial and never fully penetrates the organization.

3. Partial Implementation

Often, companies implement only a small portion of Lean principles, focusing narrowly on cost reduction or productivity improvement. Such partial approaches cause Lean to lose its essence as a comprehensive management system.

Lean is designed to create cross-functional integration among production, quality, human resources, and supply chain management. When Lean is applied only in one area without systemic and cultural support, the resulting change becomes temporary and fails to produce long-term value.

4. Limited Understanding and Workforce Capacity

Lean Management’s success depends greatly on how well human resources understand its principles and methodologies. To achieve maximum results, employees need strong analytical skills and deep process understanding.

In many cases, employees are not given sufficient training, making it difficult to recognize waste, identify root causes, or find systematic solutions. This condition makes Lean implementation stagnate at the level of formality.

Furthermore, individual capacity limitations often relate to mindset. Lean requires reflective, analytical, and collaborative thinking, while many companies still focus on short-term results.

This makes it difficult for continuous improvement to grow organically, as employees do not fully understand the meaning behind each Lean principle.

5. Difficulty Maintaining Consistency and Sustainability

Another common challenge is the decline in consistency after the initial implementation phase. Many companies begin Lean initiatives with great enthusiasm but fail to maintain momentum when quick results are not immediately visible.

In essence, Lean is a long-term journey that requires discipline, routine evaluation, and commitment to continuous improvement.

By understanding these challenges, companies can prepare a more realistic and adaptive implementation approach. Lean is not just a management tool, it is about building a disciplined, collaborative, and learning-oriented mindset.

Discover More : Smart Ways to Delegate Tasks to Improve Team Performance

Examples of Lean in Manufacturing and Service Industries

Although Lean principles originated in manufacturing, over time they have evolved into a universal approach to creating value and efficiency across sectors. Two of the most prominent fields in its application are manufacturing and services.

Manufacturing Industry

The implementation of Lean in manufacturing aims to create a seamless production system. Any activity that does not add value such as waiting, excessive movement, or overstocking is identified as muda (waste) and must be eliminated.

Toyota, for example, applies the Just in Time (JIT) principle, where materials arrive only when needed, and products are made only when there is real demand. This system is supported by the culture of jidoka “automation with a human touch.” Machines and workers are authorized to stop the production line whenever a problem occurs.

This ensures that quality is maintained at every stage, not merely inspected at the end. Standardized work is used not to restrict but to ensure that every improvement found in one line can be shared across the entire system.

Through these principles, Lean manufacturing builds a continuous learning chain: data from the production floor is used to improve workflows, reduce errors, and adjust processes for greater efficiency. The results are not only time and cost savings but also operational resilience, as every individual feels responsible for maintaining quality and performance.

Service Sector

Unlike manufacturing, which focuses on material flow, Lean in services focuses on information, communication, and human interaction flows. Here, waste takes the form of waiting times, redundant administrative steps, miscommunication, or mismatched services that fail to meet customer needs.

In hospitals, for instance, Lean is applied to streamline patient flow without reducing service quality. Value Stream Mapping is used to map the patient’s journey from registration to treatment, to identify where time and resources are wasted.

As a result, processes such as registration, lab testing, and medication delivery can be restructured for faster flow while reducing workload stress on healthcare staff.

Thus, Lean not only increases hospital efficiency but also improves patient experience and staff morale.

More importantly, Lean in services is not just about speeding up processes, it transforms how organizations think. Companies shift from being mere service providers to learning systems that continuously evolve from customer interactions.

Every complaint, delay, or error is treated as a signal to improve the system, not to blame individuals. Therefore, Lean creates a more adaptive, empathetic, and value-driven service culture.

Lean Management is not merely an efficiency method, it is a way of thinking that puts people and value at the center of every process. This philosophy teaches that operational excellence is not achieved by working harder but by working smarter.

At Arghajata Consulting, we believe that Lean transformation cannot be done through instant approaches. Every company has its own context, culture, and challenges. Therefore, we assist clients in designing realistic Lean implementation, starting from process mapping, culture-building, to team coaching in executing continuous improvement initiatives.

Contact us to discuss how Lean principles can be strategically applied in your workplace.